In shift-based operations, exceptions are expected.

Absences, late arrivals, demand fluctuations, qualification constraints, and labor rules are not edge cases. They are structural characteristics of environments that operate across shifts, locations, and roles.

The nature of the problem has always been the same. What has evolved is the ability to handle exceptions systematically, without relying on manual coordination, fragmented tools, or last-minute judgment calls.

In retail and manufacturing environments, benchmarks show that better workforce alignment during peak or disruption periods can recover up to 7% in lost sales while reducing excess labor costs by 2-8%.

Addressing this challenge requires more than faster reactions. It requires a structured way to make better decisions when reality deviates from plan.

ICRON WFM approaches exception management not as a series of isolated reactions, but as a connected operational capability that links planning, execution, and workforce rebalancing in one decision layer.

Three Pillars of Smart Exception Management

Effective exception management in shift-based operations rests on three connected pillars:

- Making the right replacement decision when coverage breaks

- Rebalancing capacity across locations when local shortages occur

- Anchoring every decision in real execution data, not assumptions

ICRON WFM brings these pillars together, allowing managers to respond to exceptions with control rather than urgency.

Pillar 1: Intelligent Coverage Recommendations

Exception management is not limited to replacing absent employees. In practice, it is about ensuring that required workload is covered, regardless of why a gap exists.

In ICRON WFM, intelligent recommendations support coverage decisions whenever workload is not met, whether due to absence, unexpected demand, open shifts, or overtime needs.

How it works

Once schedules are published and execution begins, ICRON WFM continuously evaluates workload coverage under workload management.

When a gap appears, for example:

- an employee does not show up unexpectedly

- a sickness or time-off request is approved

- an employee leaves and shifts remain open

- demand peaks beyond planned capacity

- additional work requires overtime coverage

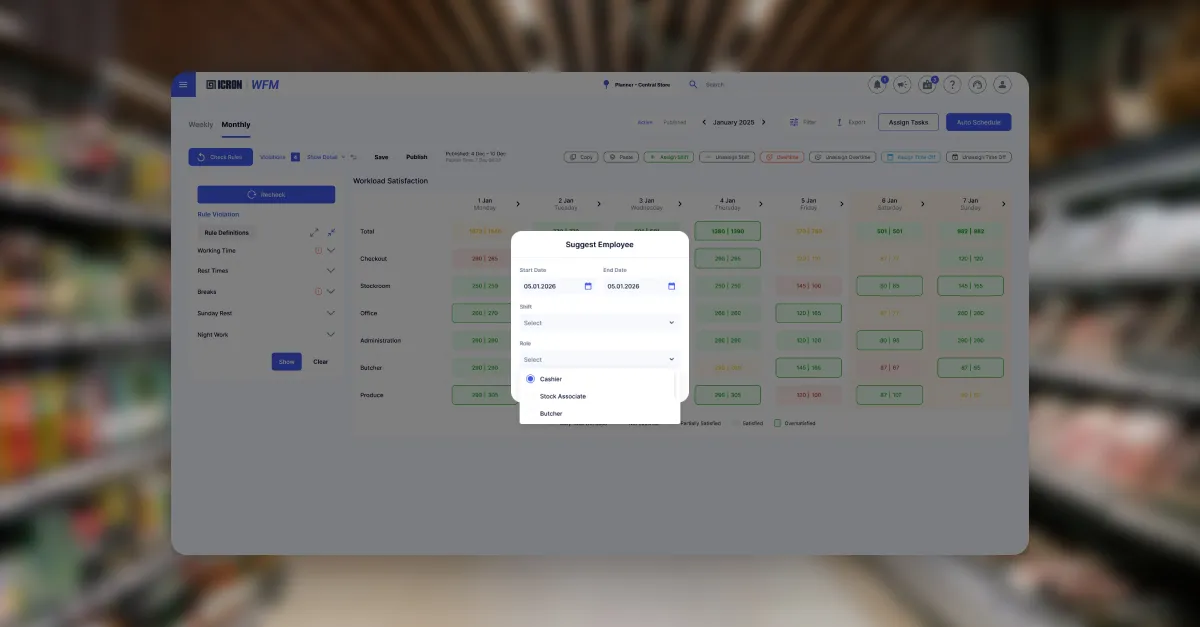

the manager can select the specific shift and role where workload is unmet and request a recommendation.

ICRON WFM then evaluates eligible employees against:

- Required role and qualifications

- Legal and corporate rules (working hours, rest, contracts)

- Leave status and availability

- Overtime balance and cost impact

- Fairness criteria based on recent workload distribution

The system presents a ranked list of eligible employees, typically showing the top options that best satisfy all constraints.

Managers can:

- Select one of the recommended employees

- Or choose an alternative, with the system clearly flagging conflicts and requiring justification

This ensures flexibility without losing control or compliance.

Replacement and overtime in the same workflow

Importantly, this mechanism applies both to replacement scenarios and overtime assignment.

- If someone is absent, the system recommends who can replace them

- If workload peaks and overtime is required, the system recommends who should take the overtime shift

- In both cases, the same rules, fairness logic, and compliance checks apply Coverage decisions are treated consistently, regardless of why the gap exists.

Why this matters in practice

Retail benchmark studies show that improved staffing alignment during high-traffic periods can increase sales by up to 7-9%. When exceptions such as no-shows or demand spikes are not resolved quickly, the impact is immediate: lost sales opportunities, longer queues, and degraded customer experience.

- In manufacturing, uncovered workload may require a certified operator or controlled overtime to keep production running safely

- In healthcare, additional workload may require assigning qualified staff (for example, a NICU nurse, or an oncology-certified nurse) while respecting fatigue and rest rules

- In retail and QSR, sudden demand spikes often require fast overtime decisions without repeatedly burdening the same employees

- In warehouses, workload peaks tied to inbound or outbound volume must be covered quickly without breaking labor constraints

Across these environments, workload gaps are addressed proactively and consistently, rather than reactively and manually.

Pillar 2: Temporary Resource Sharing Across Locations

Intelligent coverage recommendations work within a location as long as there is eligible local capacity.

But in multi-site operations, local capacity is often constrained by skills, overtime limits, or fairness rules.

When this happens, exception management must extend beyond a single location

ICRON WFM supports temporary resource sharing as a structured extension of workload coverage, not as an informal escalation.

How it works

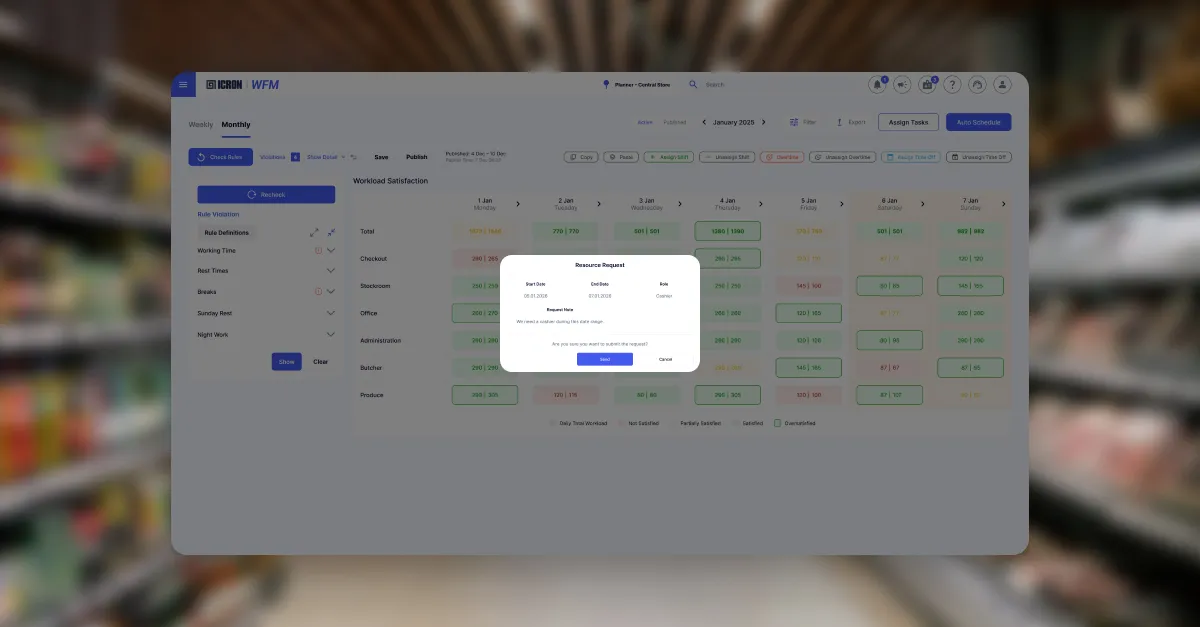

When workload cannot be fully covered within a location (even after evaluating overtime and replacement options) the manager can submit a temporary resource request.

This request specifies:

- The period during which support is needed

- The role or qualification required (for example, a cashier, a stockroom associate, or a certified machine operator)

- The location experiencing the workload gap

Once submitted, the request becomes visible to regional or central managers, who have an overview of workforce availability across nearby or related locations.

The regional manager can then:

- Select which employee will be temporarily assigned

- Confirm the assignment directly in the system

Once approved, the employee’s temporary workplace is automatically reflected on schedules, ensuring clarity for planners, employees, and reporting.

How this fits into exception management

Temporary resource sharing is not a separate process. It is a capability that allows exception management to scale beyond a single location when local options are limited.

Depending on how an organization operates, managers may attempt to cover workload locally through replacement or overtime, or they may move directly to requesting temporary support from nearby locations. ICRON WFM supports both approaches, without enforcing a fixed sequence.

All temporary assignments remain visible, planned, and governed, preserving flexibility while avoiding unmanaged last-minute staff movements.

Why this matters in practice

In manufacturing networks, labor cost benchmarks show that 2-8% of excess labor cost is often driven by over- or understaffing caused by unplanned absences and skill constraints. Structured resource sharing across sites helps absorb these exceptions without defaulting to overtime or production delays.

This capability is especially valuable in environments such as retail chains, manufacturing networks, multi-facility healthcare systems, QSR networks, and distribution operations.

- In retail and QSR, nearby stores can temporarily support each other during peak periods without adding headcount

- In manufacturing, plants or production lines can share qualified operators to prevent bottlenecks

- In healthcare, temporary support can be coordinated across units or facilities while maintaining qualification and compliance requirements

- In warehousing, labor can be flexed across sites to absorb volume surges without overreliance on overtime

Workforce capacity is treated as a shared network resource, not a fixed local constraint.

Pillar 3: Real-Time Execution Visibility with QR Punch In and Out

Exception management depends not only on planning decisions, but on knowing what is actually happening on the ground.

When execution data is not captured in real time, organizations can accumulate tens of thousands of unnecessary overtime hours annually. Studies indicate that smarter scheduling systems significantly reduce planning and payroll errors, with reported savings of up to 40,000 overtime hours per year, and enables earlier corrective action.

Without real-time execution data, managers are forced to act on assumptions, often discovering problems only after shifts have ended.

ICRON WFM brings time and attendance into the same decision layer as planning, ensuring that coverage decisions are anchored in reality.

How it works

ICRON WFM enables QR code–based punch in and punch out as part of its time and attendance capability:

- Planners generate store- or location-based QR codes

- Employees punch in and out using the ICRON WFM mobile app

- Attendance events are processed in real time

These execution events immediately feed into:

- Shift adherence monitoring

- Detection of late arrivals or no-shows

- Overtime accumulation tracking

- Identification of uncovered workload for future planning cycles

- Triggering of coverage recommendations

There is no delay between execution and visibility.

How this strengthens exception management

Real-time execution visibility ensures that exception handling is timely, precise, fair, and fast:

- No-shows and late arrivals are detected immediately (for example, a cashier missing the opening shift or a nurse arriving late for a night handover)

- Workload gaps are identified while corrective action is still possible

- Replacement, overtime, or resource-sharing decisions reflect actual worked hours, not planned ones

This prevents overreaction, unnecessary overtime, or delayed intervention.

Why this matters in practice

Across shift-based industries, execution visibility is the difference between proactive control and reactive correction.

- In manufacturing, delayed detection of absenteeism can halt production or force unplanned overtime

- In healthcare, real-time attendance supports safe staffing decisions and fatigue management for nurse managers

- In retail and QSR, immediate visibility helps store managers respond to demand surges without overstaffing later shifts

- In warehouses, execution visibility enables faster rebalancing of labor during volume spikes By closing the loop between plan and execution, exception management becomes continuous, not episodic

Why These Three Pillars Work Together As One System

These three pillars form a coherent exception management framework, without enforcing a rigid workflow.

Unmet workload can be identified through execution data, addressed locally through intelligent coverage decisions, or resolved through network-level resource sharing. Organizations can adopt and combine these capabilities in ways that reflect their operational reality and maturity.

This is what allows ICRON WFM to support exception management not as a collection of features, but as a decision-centric operating model for shift-based operations.

See Smarter Exception Management in Practice

Across industries with high shift volatility, organizations that systemize exception handling report measurable gains in decision speed, reduced overtime exposure, and more consistent coverage outcomes.

If you would like to see how ICRON WFM supports exception management in your own environment, you can request a demo here